Scope

As part of a continuing effort to identify opportunities for energy conservation, the Edison Energy Engineering Solutions team was contracted by Tishman Speyer to perform a detailed retro-commissioning and ASHRAE Level II Energy Audit project at the Chrysler Center located in Manhattan, NY. This project was executed per ASHRAE guidelines in conjunction with the Local Law 87 Energy Audit and Retro-Cx Requirements and focused on the development of Energy Conservation Measures (ECMs), which, once implemented, would promote large-scale energy efficiency and cost savings over time. The approach was driven to maximize the value (ROI) of aggregating low-cost energy improvements with capital projects, which, when combined, result in the most valuable set of ECMs possible. Additionally, part of this study focused on the major mechanical system serving the Chrysler Building as well as central plant equipment shared with 666 Third Avenue. As part of a separate effort, our team also conducted a full retro-commissioning and ASHRAE Level II Energy Audit at the 666 Third Ave. facility, which, together with the Chrysler Building, comprises the Chrysler Center.

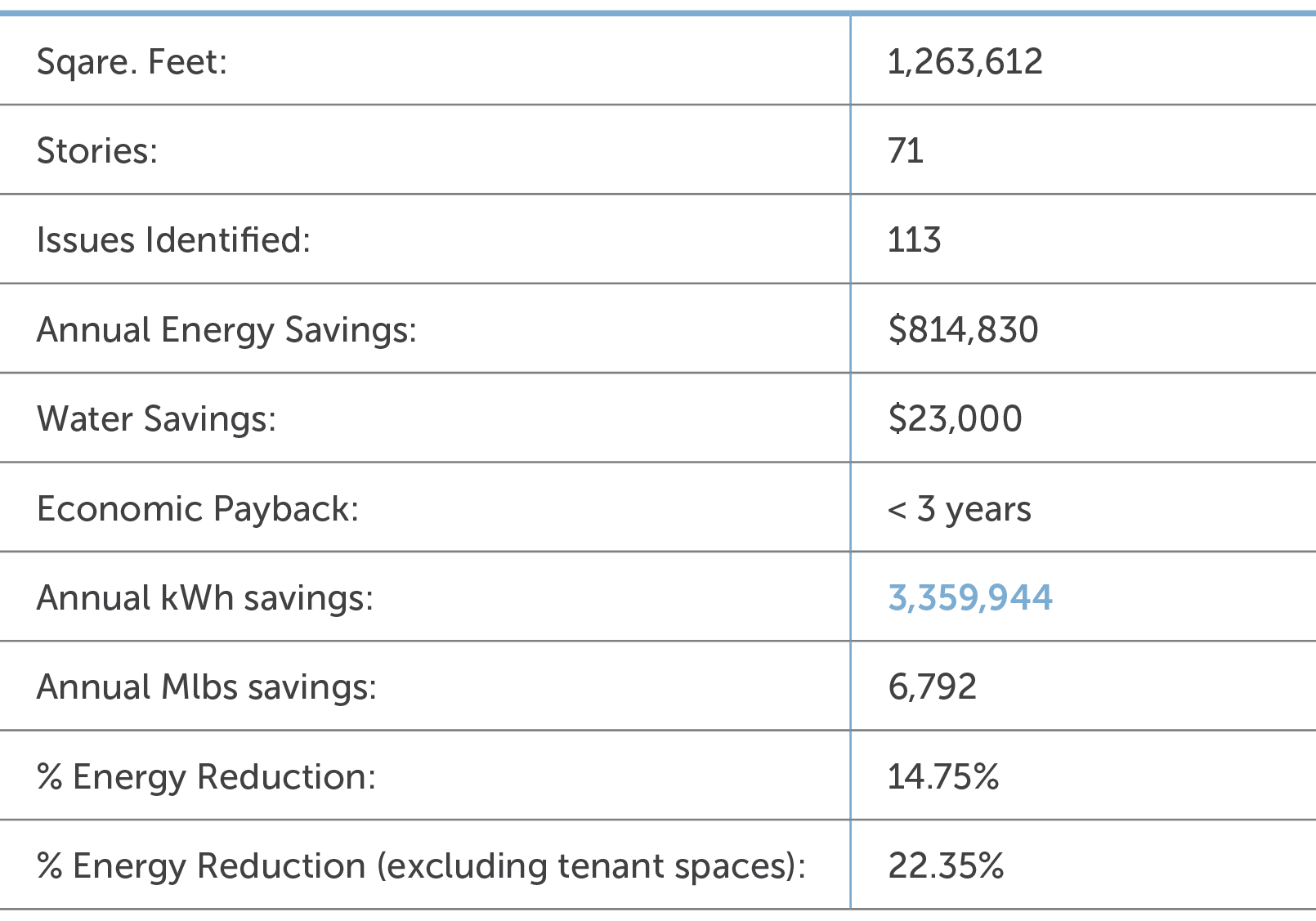

Project Results & Key Metrics:

Customer Value

The opportunities identified by the Edison Energy team were designed to further enhance and improve upon the conservation strategies already in place, as Tishman Speyer’s past efforts in energy conservation were evident in the implementation of lighting retro-fits, controls upgrades, and the energy awareness and diligence of the engineering staff. Our team identified and analyzed a number of ECMs that were aimed at reducing site energy consumption. These ECMs equated to $742,000 per year and 18% of the building’s total energy consumption (15% of base building energy consumption, excluding tenant spaces). Furthermore, based upon the results of our audit, the following ECMs were budgeted for implementation: VFDs and controls programming on all fan motors greater than 10 HP and convert from constant volume to single zone variable volume control:

- High efficiency electrically commutated motors on 2,000 fan coil units

- Variable prime chiller control sequence

- Condensate recovery system for use as cooling tower makeup water

In addition to the identification and implementation of ECMs, our team implemented an Ongoing Commissioning program at the Chrysler Center to further improve the buildings’ efficiency by expanding the commissioning activities to additional systems, as well as maintaining the buildings’ high level of efficiency. As part of this program, our team trained Tishman staff on the Ongoing Cx Process as well as providing technical training on the equipment and testing procedures. The Tishman team and Project benefited from this program in the following areas:

- Excellent return on investment

- Reduction in energy costs and budget

- Verification/validation of environmental criteria

- Reduced maintenance

- Increased system reliability

- Improved occupant comfort

- Solved long-term operating problems

Upon completion of the project, the building was awarded LEED® Gold – for Existing Buildings: Operations and Maintenance by the U.S. Green Building Council (USGBC).

Download a PDF of the Tishman Speyer Chrysler Center case study here